Dry Ice Cleaning

Dry ice cleaning uses solid carbon dioxide as a kinetic media for efficiently removing contaminants from various high-value industrial assets. Our cleaning ensures significantly superior results compared to traditional methods and does not generate a secondary waste stream, unlike solvent cleaning. Being a “dry” process, it can be applied to energised electrical equipment as well.

SUPERIOR CLEANING MINUS THE DOWNTIME

NON-TOXIC AND ENVIRONMENT FRIENDLY CLEANING

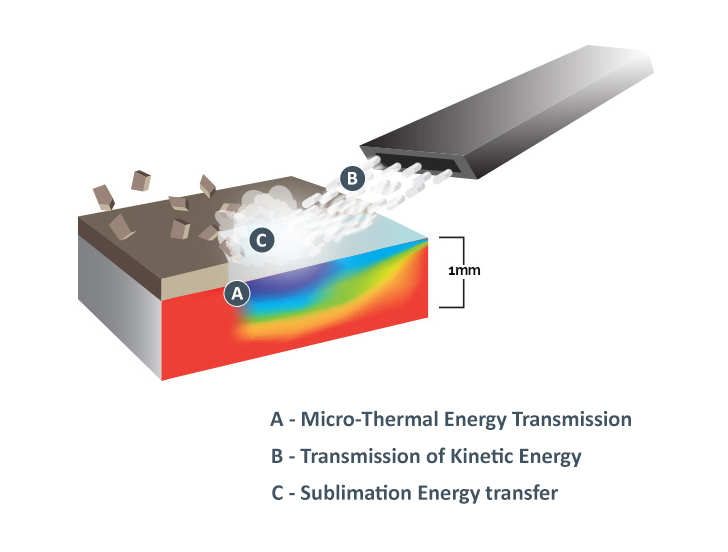

![]() Cleaning with low temperature – thermal shock effect cracks up the contaminant layer.

Cleaning with low temperature – thermal shock effect cracks up the contaminant layer.

![]() Cleaning with mechanics – pellets propelled at supersonic speed loosens the contaminant from the surface.

Cleaning with mechanics – pellets propelled at supersonic speed loosens the contaminant from the surface.

![]() Cleaning with sublimation – 700x expansion micro-explosion atomises the broken up and loosened contaminant leaving the original surface clean.

Cleaning with sublimation – 700x expansion micro-explosion atomises the broken up and loosened contaminant leaving the original surface clean.

ADVANTAGES

![]() Decreased downtime through cleaning in-situ often on live equipment

Decreased downtime through cleaning in-situ often on live equipment

![]() More thorough and superior cleaning compared to other methods

More thorough and superior cleaning compared to other methods

![]() Benign to underlying original surface – removes only the contaminant layer

Benign to underlying original surface – removes only the contaminant layer

![]() Generates no secondary waste and eliminates need for using toxic solvents for cleaning

Generates no secondary waste and eliminates need for using toxic solvents for cleaning

Minimise Downtime

Superior Cleaning

Environment Friendly

DRY ICE CLEANING APPLICATIONS

TURBINES

HEAT EXCHANGERS