Drone & ROV

NDT Inspection

Lesser Manpower Required

Quick Mobilisation High Accuracy

PIONEERING TECHNICAL INNOVATION

Drones and UAVs allow fast and flexible positioning at any height or location and can also operate within confined areas. These technologies eliminate the risk and need for direct human access. Significant improvement in speed and productivity can be achieved using drones. SPS offers revolutionary inspection services such as drone-based tactile ultrasonic thickness measurement for the first time in India.

In-House R&D Team

SPS has a dedicated in-house R&D team and facilities to design and develop innovative and pioneering technologies to help our customers inspect their assets more quickly, efficiently and safely.

Custom-Developed Drones

SPS has fully custom-developed drones that are rugged and contain several failsafe features and redundancies for operation within ferromagnetic interferences and other hazards common in industrial environments. Our drones are extensively tested and DGCA-registered, making them safe to fly in an industrial plant

DGCA-Certified Pilots

SPS follows rigorous checklists and SOP before and during each flight. Drones are piloted by our DGCA-certified pilots, who have industrial flying experience.

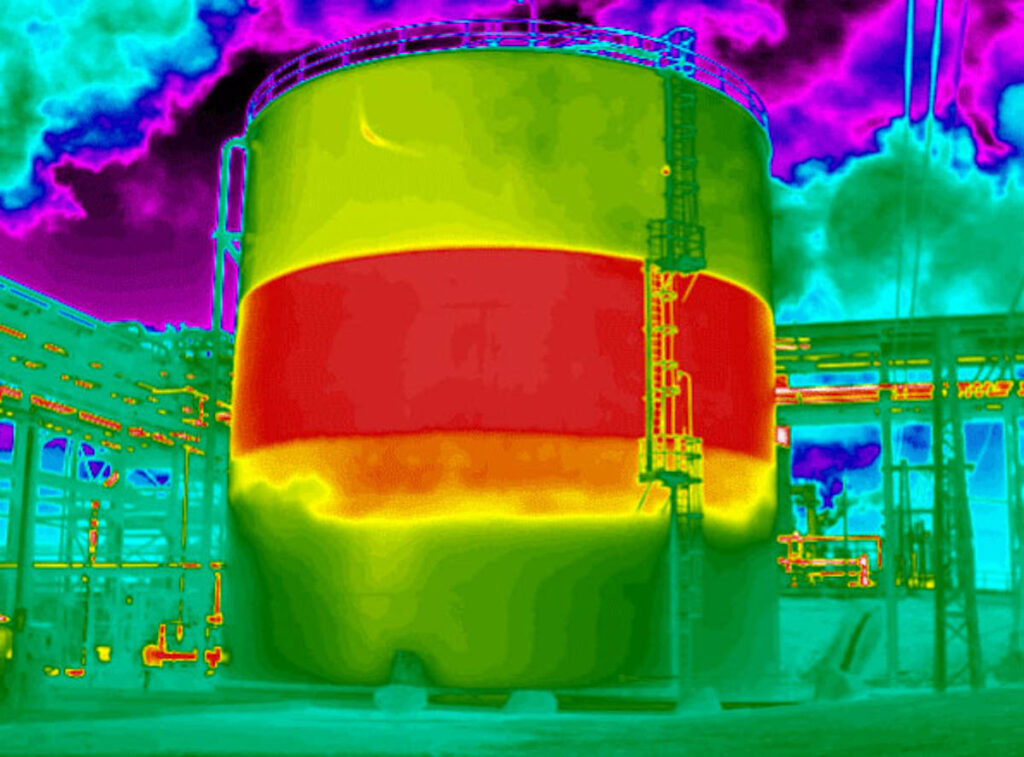

VISUAL AND INFRARED INSPECTION

Drone-based visual inspection of tall and difficult-to-reach assets using HD video and high-resolution imaging to determine anomalies, corrosion, condition monitoring, roof sheet inspection, Infrared thermography and asset access configuration.

Industrial Ultrasonic thickness measurement drone

![]() Capable of taking UT readings on surface temperatures up to 200°C

Capable of taking UT readings on surface temperatures up to 200°C

![]() Fully remote controlled

Fully remote controlled

![]() Takes readings using a drone-mounted through-coat UT transducer with real-time remote data transmission capability

Takes readings using a drone-mounted through-coat UT transducer with real-time remote data transmission capability

![]() Remote gel release for transducer contact prior to UT reading

Remote gel release for transducer contact prior to UT reading

![]() Dual on-board cameras with digital video transmission

Dual on-board cameras with digital video transmission

![]() UT transducer housed in a magnetic surface locking system with 3-axis mobility to ensure optimum probe contact

UT transducer housed in a magnetic surface locking system with 3-axis mobility to ensure optimum probe contact

![]() Capable of operating within high ferromagnetic interference zones

Capable of operating within high ferromagnetic interference zones

HOW IT WORKS

ULTRASONIC THICKNESS INSPECTION

For the first time in India, SPS has developed and proven unique solutions for tactile Ultrasonic Thickness (UT) inspection of steel structures.

ROVER BASED ROBOTIC ULTRASONIC THICKNESS INSPECTION OF PIPES

For Ultrasonic Thickness (UT) inspections in areas inaccessible or not conducive to drones, we offer a cutting-edge range of robotic crawlers designed to deliver precision and reliability.

Our specialised rover fleet is built to perform Ultrasonic Thickness (UT) inspections in complex industrial environments, ensuring 360-degree circumferential readings where drones can’t operate—such as the underside of pipes, vertical surfaces, and areas with restricted access (e.g., 180° and 270° positions on a pipeline). These rovers are specifically designed to handle pipe ultrasonic thickness measurement, ensuring accurate and reliable readings even in the most challenging conditions.

![]() Dual-Mode Inspection – Visual & ultrasonic thickness (UT) inspection

Dual-Mode Inspection – Visual & ultrasonic thickness (UT) inspection

![]() Magnetic Omni-directional Mobility – For ferromagnetic pipes, tanks, ducts, and stacks

Magnetic Omni-directional Mobility – For ferromagnetic pipes, tanks, ducts, and stacks

![]() Flange/barrier crossing ability – Crosses barriers up to 100 mm in height.

Flange/barrier crossing ability – Crosses barriers up to 100 mm in height.

![]() Long Battery Life – Extended operations with an integrated power management

Long Battery Life – Extended operations with an integrated power management

![]() Gas Detection – Detects methane, CO, and can be configured for other gases

Gas Detection – Detects methane, CO, and can be configured for other gases

![]() Real-Time Visuals – 4K digital Video Camera for live monitoring

Real-Time Visuals – 4K digital Video Camera for live monitoring

![]() Remote Controlled – Ensuring operator safety in hazardous zones

Remote Controlled – Ensuring operator safety in hazardous zones

HOW IT WORKS

As India’s first solution provider offering both drone-based Ultrasonic Thickness inspection and rover-based Ultrasonic Thickness inspection, SPS is revolutionising industrial automation. Our advanced robotic crawlers complement UAV solutions, ensuring a seamless, data-driven approach for comprehensive asset integrity management.

INSIGHT360™ Internal Inspection of Vertical Confined Spaces

A state-of-the-art internal visual inspection system designed for vertically straight hollow and confined spaces such as chimneys, stacks, tanks, hoppers, bunkers, and scrubbers. Engineered for unparalleled stability, precision, and safety, INSIGHT360™ redefines how critical inspections are performed at height.

With auto-equipped illumination and 360° visual coverage, this solution enables comprehensive internal mapping of industrial assets—without the need for traditional, high-risk access methods.

Why Choose INSIGHT360™?

![]() Advanced inspection without scaffolding

Advanced inspection without scaffolding

![]() 360° internal visual coverage at all heights with real-time asset mapping

360° internal visual coverage at all heights with real-time asset mapping

![]() Built-in illumination for clear visibility in low-light environments

Built-in illumination for clear visibility in low-light environments

![]() Rapid deployment and faster inspection cycles

Rapid deployment and faster inspection cycles

![]() Delivers actionable insights for smarter maintenance decisions

Delivers actionable insights for smarter maintenance decisions

![]() Ideal for chimneys, stacks, tanks, hoppers, scrubbers, and more

Ideal for chimneys, stacks, tanks, hoppers, scrubbers, and more