Cleaning

DRY ICE CLEANING

NON-TOXIC AND ENVIRONMENT FRIENDLY CLEANING

Advantages

Minimise Downtime

Superior Cleaning

Environment Friendly

DRY ICE CLEANING APPLICATIONS

TURBINES

HEAT EXCHANGERS

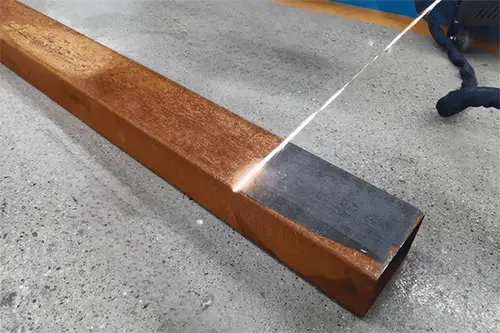

LASER CLEANING

Precision Cleaning. Zero Damage. Zero Chemicals.

Laser Cleaning is a cutting-edge technology that uses concentrated laser beams to safely and precisely remove rust, paint, coatings, and surface contaminants—without the use of abrasive materials, chemicals, or water.

How It Works

Laser Ablation:

A high-energy laser beam targets unwanted layers on a surface, vaporizing or breaking down rust, paint, oil, or residue while leaving the base material intact.

Non-Contact Operation:

The laser never touches the surface, eliminating the risk of abrasion, warping, or distortion—ideal for delicate or complex components.

Clean, Green Technology:

No solvents. No media blasting. No secondary waste. Just clean surfaces and minimal post-cleaning requirements.

High-Efficiency

Non-Contact

Eco-Friendly

Advantages

HYDROJET CLEANING

High-Pressure Cleaning for Maximum Efficiency

Hydrojet Cleaning—also known as high-pressure water jetting—is a versatile and powerful cleaning method that uses pressurized water to remove tough deposits, scale, grease, and blockages from industrial surfaces and equipment. It is completely chemical-free and highly effective for restoring performance and extending equipment life.

How It Works

High-Pressure Water Jets:

Water is pressurized up to 40,000 PSI and directed through specialized nozzles to break down and flush away contaminants like scale, rust, sludge, and grease.

No Abrasives or Chemicals:

The method relies purely on the kinetic energy of water—making it safe for both operators and the environment.

Deep Internal Cleaning:

Hydrojetting reaches inside tubes, pipes, tanks, and complex geometries that other methods can’t clean effectively.

Powerful

Precise

Industrial-Grade

Advantages